Whitford QAC Approval

Plastic Coatings Ltd have just successfully completed our 8th Audit process for the Whitford Quality Approved Coater (QAC) status!

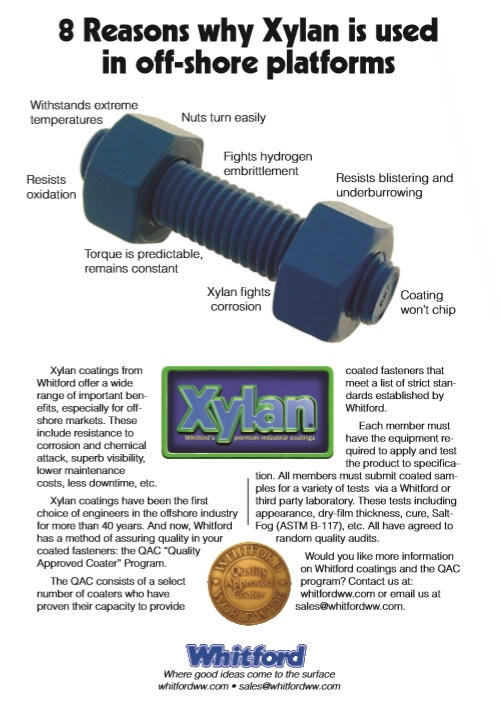

Back in July 2005, PCL were amongst a select few companies that were selected by Whitford World Wide (the manufacturers of Xylan and Xylar range of flouropolymer materials) for a new supply chain approval that would offer specifiers of Whitford materials a greater level of confidence around the material applicators.

The ‘Quality Approved Coater’ (QAC) status would differ from ‘Quality Recommended Coaters’ in that Whitford would carry out a detailed compliance audit that would verify an applicators processes and controls.

The QAC audit covers all the key aspects of using the materials correctly to ensure the very best coating performance in the field. The areas covered include –

- Storage of material, correct storage temperature and use-by-dates adhered to

- Pre-treatment process control (including grit blasting and phosphate treatments)

- Material application to correct standards

- Coating thicknesses, Adhesion and Cure tests

- Oven cure profile verification

- Samples tested (Salt Spray Test) to ASTM B117 to further verify correct material application techniques

The latest approval certificate (see download page) was issued following successful audit of our brand new plant and equipment in our new premises back in 2017. Our new certificate will be issued when the latest controlled samples have passed the performance testing back at the Whitford Laboratory.

Why not contact our sales team now to see how Plastic Coatings proven material application systems can help solve your coating problems?