Specialist shot peening services.

Shot Peening is a cold working process, in which the surfaces of components are subjected to substantial impact from small spherical pieces of media called ‘shot’. Each individual ball of shot acts as a tiny peening hammer, creating small indentations or dimples on the surface. This causes plastic deformation in a shallow layer of the component. When the indentations in the surface overlap, the fatigue life of the component is greatly increased.

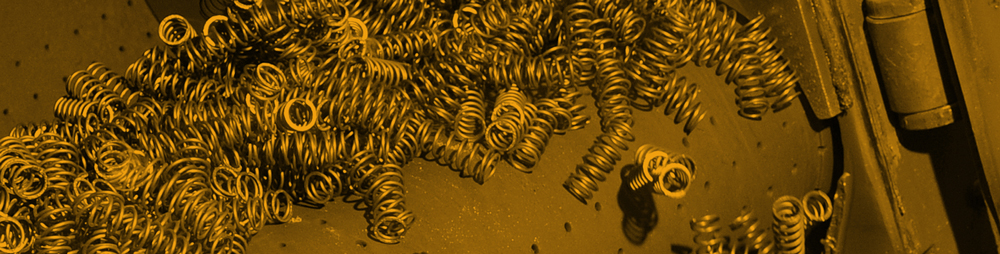

In the Spring and Gear Manufacturing industries, Shot Peening is used extensively where the benefits of the process are used predominantly to enhance product longevity.

Some of the benefits are as follows

- Increased fatigue life

- Increased corrosion fatigue resistance

- Increased stress corrosion cracking resistance (SCC resistance)

- Increased surface hardness caused by the cold working effect of Shot Peening

- Increased surface roughness of Shot Peened parts allows for better adhesion of subsequent coatings that may be applied (if required)

Typical components that benefit from Shot Peening:

- Compression Springs

- Torsion Springs

- Valve Springs

- Coil Springs

- Die Springs

- Leaf Springs

- Torsion Bars

- Gears

- Specialised Fasteners

Typical Post-Peening Treatments:

- Stress Relieving

- Phosphating

- Oiling

- Organic Coatings

- Plating

- Electrophoretic Coating

- Powder Coating

Need a quote for an upcoming project?

Call or email us for a free quote.

-

- Customer approvals

-

- Other approvals